When we are talking about a hot tapping procedure on a basic level, it is basically an installation procedure that connects pipelines while they are in service. Such a procedure is implemented when there are crucial repairs demanded by the pipelines, it can be the result of internal damage or corrosion. Hot tapping equipment can also be implemented if the pipe needs to add or modify the current pipe network. Let us learn more about the procedure so that you get a fair idea on its working.

First of all, you need to understand the complexity of the process and the various risks involved. As the pipe workers need to work on a live network of pipes most of the time, the stakes are high and all the safety rules and regulations must be addressed for the same. For your information, the American Petroleum Institute or API has issued a set of safe hot tapping guidelines to ensure safety of the engineers.

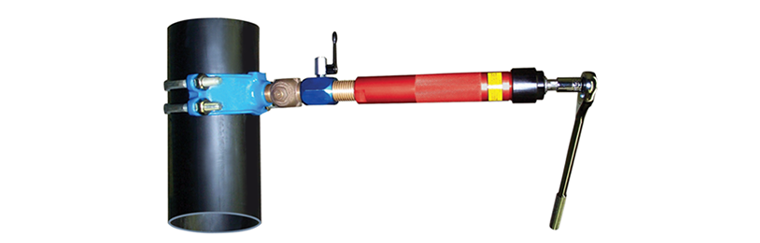

Hot taps are highly efficient in integrating themselves into pressurized system with the help of drilling/cutting a pipeline or a network of pipes. For the completion of the project, engineers require a tapping machine along the housing or cutter. There can be times when mechanical fittings can be used for the purpose of taps over the pipes. That being said, they must comply with the criteria that are designed to perfectly fit the pipeline’s dimensions. In addition to that, they should also comply with fabrication, welding and NDT (Non-Destructive Testing) standards so that maximum safety and efficiency is ensured.

As for the working mechanism of the process, it is a continuous process which basically assists in cutting through the pipe wall in a manner that the pipe is dismembered in the same shape as the hot tap. It is called coupon in the industry. Once the cutter has accomplished this task, the hot tapping tool machine halts its operation and the valves are closed again.

After reading all this, you must be confused as to which option should you opt for. There are numerous industry leading and patented features that you should look for, some of these are: rotary pressure seals, four fixed feeds to accommodate different pipeline conditions, and helical gear drive. You can choose low pressure machines or high-pressure machines according to your requirements and the kind of project that you are undertaking. The former can be used for ease of use with a single speed feed gearbox and either a hydraulic or pneumatic front. The latter can be used for extreme levels of accuracy and a variable auto feed to complement various cutting conditions.

Make a note of this post and find some of the best hot tapping machine in the market.

#hot tapping tool #hot tap equipment