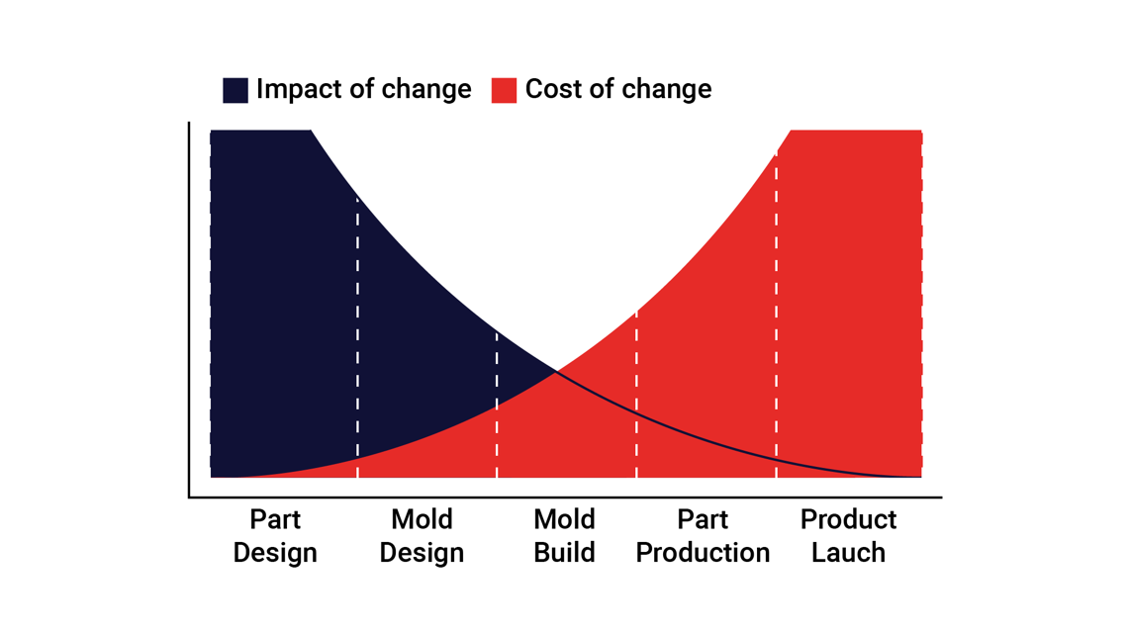

The definition of design for manufacturability (DFM) goes as follow: “The general engineering practice of designing products in such a way that they are easy to manufacture” [0]. Doing so will invariably improve the return on investment by reducing cost and avoiding problems during the manufacturing process. DFM allows problems to be caught when the cost of error is the smallest (i.e. when the part isn’t being made yet). Even if a part is manufacturable, one should always consider whether it could be manufactured faster and/or cheaper using DFM principles.

For computer numerical control machining (CNC machining) the cost is mostly driven by the machines time. This encompass the time the machine is being used, the setup time and the time to program the machine for the task. The time is also heavily affected by the material being used, the tolerances that are acceptable and the complexity of the part. If the part is to be designed for manufacturability, the designer needs to keep all these concepts in mind and balance them properly.

In this blog post, we will look at a few examples of DFM in action along with a review of tools and technique to programmatically automate the review process. If you want to learn more about different ways of saving up on cost in CNC machining, take a look at one of our previous blog post “10 méthodes pour économiser sur l’usinage CNC”. Here are a few examples of application of DFM.

Sharp Corners

An obvious change that one can make to a design to make it easier to machine is avoiding sharp corner. If we look at a turning process [1] for two parts presented in figure 1, the panel 1A makes more aesthetic sense. However, since a turning process is a single point cutting tool removing material from a rotating workpiece to form a cylindrical shape, it is impossible to get this type of right angle with only the tool as every tool has some radius. Therefore, to have a sharp corner, one need to manually remove the rounded corner. Leaving this slight curvature that fits with the piece used for the turning process as seen in the panel 1B greatly simplifies the machining process and therefore reduces the machining time.

#manufacturing #engineering #deep-learning #matlab #python